WHAT WE SUPPLY?

Sino Power industrial Co., Limited is located in Shanghai City, It is a private joint-stock enterprise specialized in metal sheet further processing machinery, steel pipe making machinery, metal sheet coating and laminating machinery and other engineering projects. SinoPower main products are as follows:

1. Metal sheet further processing equipment

1.1. Metal coil slitting machine (slit coil to strip)

1.2 Cut to length machine (cut coil to plate)

1.3 ERW welded pipe mill (welding strip to pipe)

2. Metal sheet coating / Laminating Equipment

2.1. Steel sheet color coating production line (PPGI,PPGL,for building roof or wall)

2.2 Aluminum sheet color coating production line (for door, window,etc)

2.4 Steel sheet laminating machine (for building material, with PVC,PET,aluminum foil)

2.5 ACP/ACM aluminum composite panel production line (decorative materials of wall)

2.6 VCM/PCM household appliance plate production line

2.7 Hot-melt metal sheet laminating machine(for metal packaging materials)

1.1 Metal coil slitting machine (slit coil to strip)

1) Machine use: coil slitting machine is a shearing operation that slit a large width metal coil into narrower strip.

2) Technical Flow Chart:

Carrying coil car→de-coiler→Feeding guide device→pinching roller→leveling→coil head shearing→looping table→Side guiding device→Disc shear→Curling machine→looping table→Tension table→Re-coiler→Discharging car→Hydraulic control→Electric control

3) Coil material: CR, HR,HRPO, Stainless Steel, GI, PPGI,Copper, etc

4) Coil thinkness: 0.2-25 mm

5) Coil weight: up to 30 tons

1.2 Cut to length machine (cut coil to plate)

1) Machine use: metal sheet cut to length machine line is a shearing operation that cut a large length metal coil into narrower plate.

2) Technical Flow Chart:

carrying coil car→ hydraulic uncoiler→ feeding guide plate→ pair pinching roller, five rollers leveling→ coil head cutting→ front looping table→ side guiding table→ pinching machine→ disc slitting→ curling machine→ back looping table→ pre-feeding coils→ tension table→ rewinding→ discharging car→ hydraulic bracket→ Electric control

3) Coil material: CR, HR,HRPO, Stainless Steel, GI, PPGI,Copper, etc

4) Coil thinkness: 0.2-25 mm

5) Final product length: 1-9m

6) Type: Fly shear, high speed type, normal speed type

1.3 ERW welded pipe mill (welding strip to pipe)

1) Machine use: Carbon steel tube mill is a series of tube machines that builds longitudinal weld seam pipe with steel strips of certain width

2) Technical Flow Chart:

Raw material (steel coil) → uncoiling → shearing and butt-welding → material accumulating → non-power leveling →mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → run-out table

3) Pipe size: 10-355mm

4) Pipe thickness: 0.2 - 12mm

5) pipe material: Carbon steel , mild Iron, etc

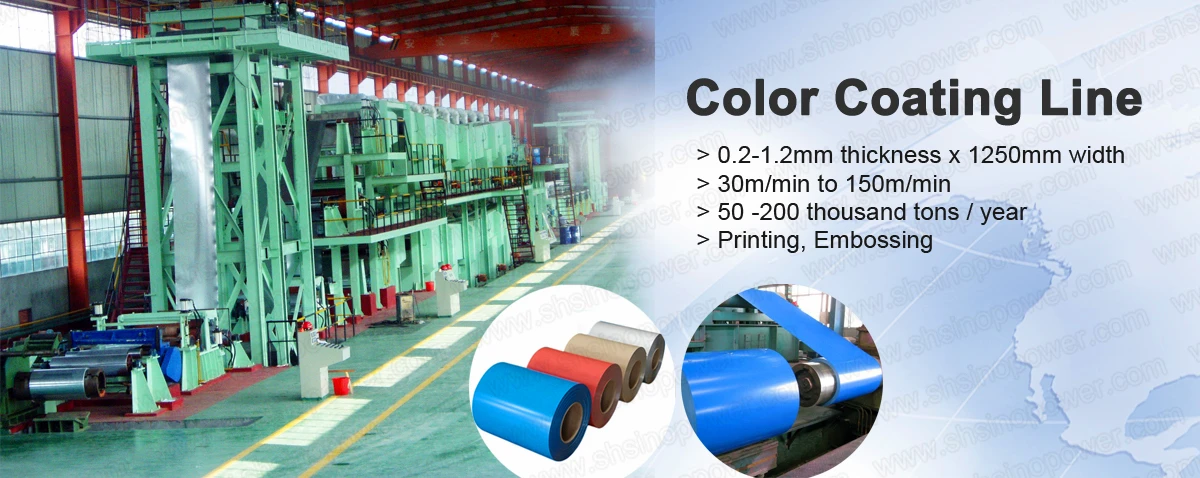

2.1 Steel sheet color coating production line (PPGI,PPGL,for building roof or wall)

Coil color-coated production line is the completely equipment to continuous-rolling coating the multilayer organic coating and overprinting a variety of color patterns on the surface of steel coil after degreasing, phosphating and passivation.

1) Main machine:Unwinding machine, sewing machine (welding machine), tension machine, stocker, degreasing cleaning unit, roll coater, printing machine, curing oven, shearing machine, rewinder and other equipment.

2) Substrate material: electro-galvanized, hot-dip galvanized, hot-dip galvanized, cold-rolled steel, etc.

3) Main Organic coating: SMP, HDP, PVDF etc.

4) Coil width: 600 ~ 1500 mm

5) Coil thickness: 0.15 ~ 1.5mm

6) Outer diameter of steel coil:φ800~2000mm

7) Process speed: 25 ~ 150m/min

8) Coating thickness: 5 ~ 25μm

9) Printing layer thickness: ≤ 1μm (ink or polyester)

10) Production capacity: 50,000 to 200,000 tons/year

11) Energy types: electricity, natural gas, liquefied petroleum gas, coal gas, steam, air-pressure gas, etc.

2.2 Aluminum sheet color coating machine line (for door, window,etc)

Aluminum coil color-coated production line is the completely equipment to continuous-rolling coating the multilayer organic coating and overprinting a variety of color patterns on the surface of aluminum coil after degreasing, phosphating and passivation.

1) raw material aluminum coil material: 1100H18 3004H24 5052H24

2) coating types: fluorocarbon (PVDF), polyester (PE), acrylic (AC)

3) aluminum coil width: 800 ~ 1250 mm

4) aluminum coil thickness: 0.02 ~ 0.3mm

5) maximum roll weight: ≤ 10 tons

6) coating thickness: 5 ~ 25μm

7) process speed: ≤ 60 meters / min

8) Energy types: electricity, natural gas, liquefied petroleum gas, gas, air pressure, etc.

2.3 Steel sheet coil laminating machine (for building material, with PVC,PET,aluminum foil)

Steel sheet coil laminating machine is the completely production line to degreasing, phosphating and passivation first, second step is to continuous-rolling coating the gule or multilayer organic coating on the sheet surface, third step is to laminating the PVC, PET or other film by laminator after baking the sheetl to process temperature.

The final products are mainly used for steel wood door panels, interior decorative panels, etc.

Steel sheet coil laminating production line is consists of uncoiler, sewing machine (welding machine), tension machine, stocker, degreasing cleaning unit, roll coater, curing oven, shearing machine, winder and other equipment.

Front can be achieved: 1 coating, 1 baking, laminating with PVC, PET film + protective film fits.

The back can be achieved: 1 coating, 1 baking. laminating with PVC, PET film + protective film fits.

1) substrate material: cold rolled steel, galvanized sheet, PPGI, Tin plate etc.

2) strip width: 600 ~ 1250 mm

3) strip thickness: 0.35 ~ 2.0mm

4) outer diameter of steel coil:φ800~1800mm

5) process speed: 20 ~ 40m/min

6) coating thickness: single dry film thickness 5 ~ 25μ

7) Production capacity: 5 to 80,000 tons/year

8) Energy types: electricity, natural gas, liquefied petroleum gas, coal gas, steam, air-pressure gas, etc.

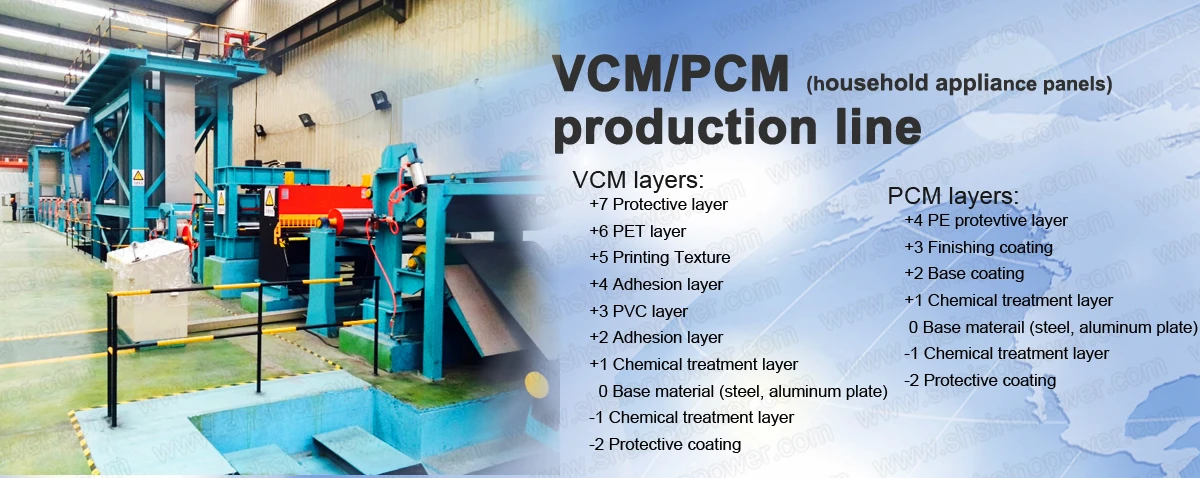

2.6 VCM/PCM household appliance plate production line

VCM: VCM is film-liminated sheet,which mainly refer to composite materials for household appliances liminated with various functional composite films. Commonly used composite films include PVC, PET, and PP.

VCM series products have a good mirror effect, rich patterns, beautiful appearance and excellent processing, surface decoration, corrosion resistance, scratch resistance, etc. VCM plate can achieve high light, matt, pearlescent effect or metal texture, while Coupled with exquisite patterns and pearlescent effects, it is synonymous with luxury and fashion.

VCM products are mainly used in refrigerators, washing machines and other home appliances panel as well as some high-grade water heaters, building doors and other fields.

PCM:

PCM is color-coated sheet, which mainly refer to the composite materials coated with organic coatings and composite materials for home appliances.

Low-end PCM products are mainly used for building materials (steel tile and sandwich panels, etc.),

High-end PCM products are mainly used as the rear pannel and side pannel of refrigerators, washing machines and other appliances and microwave ovens, water heaters, small appliances and other products.

1) Main substrate: Cold-rolled steel sheet, hot dip galvanized steel sheet, electro-galvanized steel sheet, aluminum sheet, stainless steel sheet, etc.

2) Thickness of substrate thickness: 0.2 to 1.2 (mm)

3) Board width Width: <=1350 (mm)

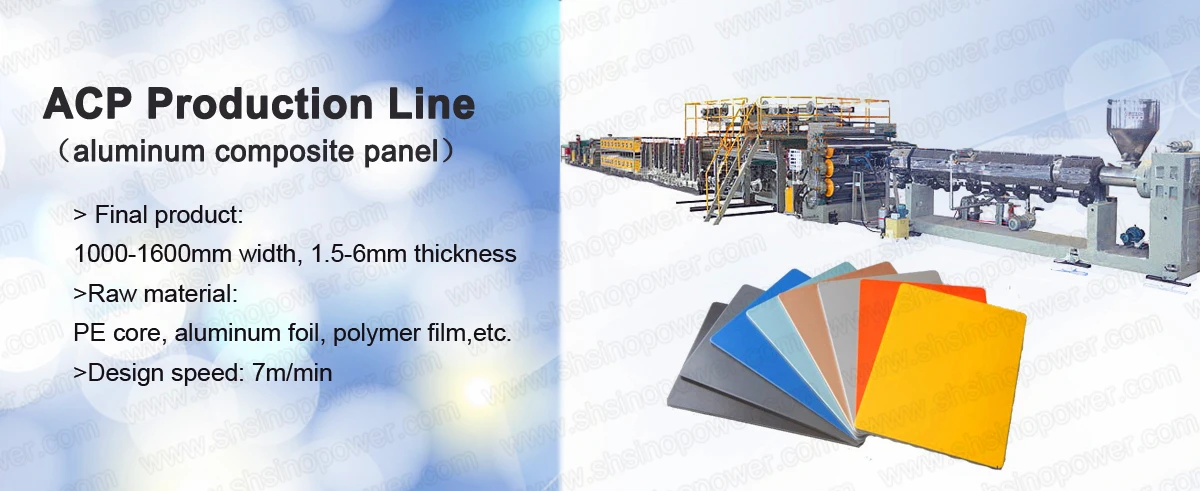

2.5 ACP/ACM aluminum composite panel production line (decorative materials of wall)

Aluminium-plastic composite panel is a kind of composite panel with plastic as core material and surface composite decorative painting aluminum. ACP always use as building decorative panel.

The production line mainly consists of extruders, three-roll calenders, aluminum foil unwinders, laminators, shears and other equipment.

1) Raw materials

1.1: PE Core Materials: LDPE, HDPE Low, High Density Polyethylene or PE Recycled Materials

1.2: Aluminum Coil: Width: 1000-1600mm, thickness: 0.02-0.5mm, weight: 5000 kg/volume, maximum outside diameter: Φ1500mm, roll diameter: Φ150/Φ405mm

1.3: Polymer film: width: 1000-1600mm,thickness: 0.02-0.05mm, weight: 60-80kg/roll

1.4: Protective Film: Width: 1000-1600mm, thickness: 0.03-0.08mm, weight: 60-80kg/roll

2) Finished aluminum plastic composite board

2.1: Width: 1000-1600mm

2.2: Thickness: 1.5-6mm (with the board difference ≤0.03mm)

2.3: Length: set according to production needs

3) Equipment speed: Design maximum speed 7m/min,

4) Production capacity:aroun 1 million square meter per year

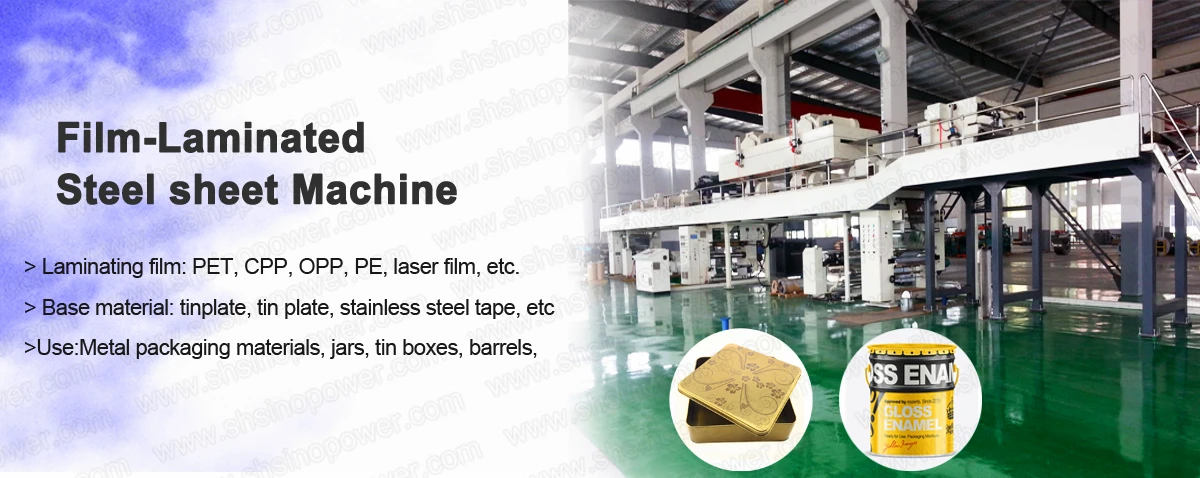

2.7 Hot-melt metal sheet laminating machine(for metal packaging materials)

Film-laminated steel sheet panel production line is a processing technology to laminate the plastic films and metal sheet by high-temperature hot pressing.

Film-laminated steel sheet is use for making can, building materials interiors, hoe appliance housings and ship interiors, etc.

1) Composite materials: tinplate, tin plate, stainless steel tape, etc.

2) Film material: PET, CPP, OPP, PE, laser film, etc.

3) Composite width: 300-1400mm

4) Compound speed: 60m/min

5) Unwinding diameter: 1500mm

6) Rolling diameter: 1500mm

7) Unwinding tension control: Automatic constant tension control of magnetic powder brake

8) Winding tension control: Inverter automatic constant tension control

9) Coating method: Gravure coating